2025年8月22日星期五

How Injection Molding Glass fiber reinforced nylon combustion solution

2025年7月10日星期四

Automotive Clip And Fastener manufacturer in China

2024年10月30日星期三

Precision Injection molding for Smart wearable device

2024年9月9日星期一

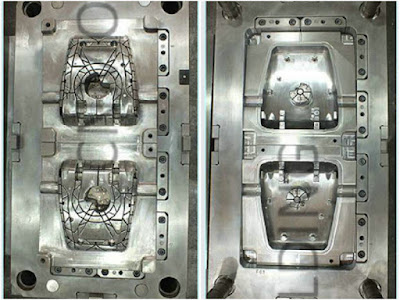

How About Precision Injection Mold Manufacturing Process

2024年2月22日星期四

2023年9月5日星期二

TRITAN COPOLYESTER Plastic Product Manufacturer in China

2023年7月21日星期五

The truth about the so-called Chinese injection molding company ranking

2023年4月14日星期五

Electric Car Pipeline Joint-15

2023年1月10日星期二

Electric Car Pipeline Joint-7

2022年12月11日星期日

Electric Car Pipeline Joint-6

2022年11月18日星期五

Electric vehicle pipeline joint -2

2021年8月15日星期日

Plastic medical products manufacturer in China

2021年6月4日星期五

What are the different types of molds?

I. Mold classification:

Classification by hardness: soft mold and hard mold (quenching treatment).

Classification by Grade Quality: Grade 1 Grade 3 by difficulty: Grade A B Class C Class D by mold size: super large medium small

II. Definition of mold hard die and soft mold:

1, mold hardness: soft mold, hard mode 1) Soft mold: mold steel has been pre-hard, no quenching treatment, but the hardness is low, HB below 400, the production life is less than 500,000 times, widely used.

2) hardened mold: the mold steel is annealed, divided into two rough machinings and finishing. After rough processing, the hardness is above HRC48 °. Keep the processing allowance of about 0.2. After rough processing, the tooling will have deformation to prevent the finishing can not meet the requirements. Production life is over 50 ~ 1 million times, with the most applications of small molds.

III. Mold quality grade: Grade I, Grade III, Grade I mold quality

1, mold: must be capable of one million or more opening times. This is the primary mold, the customer requires to make the best mold with the best materials and accessories.

2. The requirements of Grade I mold are as follows:

(1) Detailed mold design (connecting the computer drawings and materials);

(2) Most mold embryo hardness

To have an HB280;

(3) The core shall be hardened by all HRC50, positions, and accessories;

(4) Medicare side division pipe jacking pin;

(5) line position must have wear-resistant pieces;

(6) temperature control monitor shall be installed in mold, brother, or position;

(7) It is recommended to make all the cooling water channels with nickel plating (ELECTROLESS NICKEL PLATING) intended to prevent rust and easy cleaning;

(8) The positioning lock shall be added to the mold line.

learn more from quora or about all kind of injection mold type here

2021年5月25日星期二

Traditional, High - speed and Precision Injection molding

As we all know, injection molding production is pursuing "high quality, efficiency, low consumption", that is, the pursuit of profit maximization. However, the development of things needs a process, rather than overnight, the development of injection molding, and in different stages of development, the focus is different.

Traditional injection molding

The initial traditional injection molding is a priority to guarantee the normal period, the quality can be appropriately relaxed, not to mention the good rate of production and production efficiency. At that time, the technical master reflected in that others can not adjust qualified samples sample mold, as long as you can call out (no matter you spent one or a day a night or three days or two nights), you are a "cow" person, you are the hero. In view of this, leading to the high adverse rate of product products, many rely on human processing (water cutting inlet, batch cutting, pressing edge, smelting device correction deformation, etc. ), long production cycle, quality cannot be guaranteed, long - term vicious cycle of rework. Although now the traditional injection molding has been greatly improved, the man-machine ratio and labor intensity are still very high.

High-speed injection molding

High-speed injection molding relative to traditional injection molding, reduce the human-machine ratio, reduce labor intensity, with mechanical automation to replace most actions of people, reflect "quantity"; this process, high requirements for mechanical automation and assembly line operation. Qualified technical masters, not only to see if you can debug the OK model but also to consider the stability and operability of production. If you do not reach the set expectations, your model is "beautiful", it is just a model for viewing, and you cannot become the "guide" of mass production.

Precision injection molding

Precision injection molding is developed on the basis of high-speed injection molding, is specialized in the production of high value-added products, refers to an injection molding method difficult to meet the requirements of conventional injection molding machine and conventional injection molding process. Reflect "quality" to gain credibility, to "quantity" to gain profit. The precision of precision plastic parts includes size precision, shape precision, and surface precision, corresponding to size tolerance, shape tolerance, and surface roughness respectively, where size precision is an important quality index of manufacturing and use of plastic parts.

There are many factors affecting the quality and size precision of precision injection molding products, such as material selection, mold design and processing, precision injection molding machine, molding technology, the level of molding personnel and production management, etc.

Specific requirements are:

( 1) The size accuracy is high and small tolerance, i. e. high precision size boundary;

(2) product weight repetition accuracy is high, requiring day, month, year size stability;

(3) mold is good, rigid material, size accuracy, smoothness of the type cavity and positioning accuracy between templates are high;

(4) replaces replace conventional syringe;

(5)The adopts the precision injection molding process;

( 6) Select materials suitable for precision injection molding.

reference from https://www.quora.com/Why-is-precision-injection-molding-difficult

2021年5月23日星期日

Gini coefficient of the Chinese

The Gini coefficient is fully applicable to China.

The higher Gini coefficient in the past two years reflects the challenges in the adjustment of China's income distribution.

The main performance is the widening regional gap. Now the problem is that some people in society is not appropriate, one is to the region,

Urban and rural differences distort as class differences; the second is to ignore the size differences of economies and exaggerate the severity of the problem.

I read a paper on CFPS income Gini coefficient decomposition as if written by some researcher at Renmin University involved in the survey. The CFPS Gini coefficient is 0.55, the urban-rural gap contributes 0.24, and the regional gap contributes 0.20.

That is to say, the main source of income inequality lies in inequality between urban and rural areas and regional inequality, while the class differences between the inhabitants of cities or villages in the same region are small.

In 2019, Gansu GDP was about $ 5, 000 per capita, $ 18, 000, almost 3.5 times, U. S. 29, 000, the least developed Bavaria, $ 64, 000, more than twice; Japan is almost the gap.

Since 2000, the regional gap in China has generally been narrowed, that is, the growth rate of economically developed places is lower than that of economically underdeveloped places. However, in the past two years, we have bucked the trend, the growth rate of economically developed areas is moderate, and some economically less developed areas have grown particularly slow, widening the regional gap.

These two problems are the key to solving the imbalance in income distribution, rather than imagining the "class struggle" and what to "fight the local tyrants and divide the fields". At the 19th National Congress of the CPC, the Central Committee, aiming at the current situation of China's development, directly defined "the contradiction between the people' s yearning for a better life and the unbalanced and inadequate development" as the principal contradiction at present, and put the imbalance before the insufficiency,

The attitude is clear that —— is to actively manage these two gaps so that more people can enjoy the benefits of development.

Q: Does the Gini coefficient reflect more social inequality than that in most countries?

A: China has a huge volume and a huge population. which must be taken into consideration in transnational comparison, but it is undeniable that in China currently,

the degree of social inequality is still high, which is a common problem in emerging countries. Take Japan, for example, which has almost no gap between urban and rural development, the most developed region is about twice the GDP per capita of the least developed region (3.5 times in China),

Income between different industries is also relatively average, and its social inequality is certainly much better than our country. But the Gini coefficient in Brazil and Mexico is also lower than in China, which may be related to the volume, with only one or 20 million people. I think that our society's

The degree of inequality must be significantly higher than the developed countries like Japan and Germany, but not significantly higher than Brazil and Mexico

Emerging countries will not be higher than the United States that tolerate the rich and the poor and even actively separate social strata.

Q: you say the class gap is not big, I am in Guangzhou, Beijing, people three apartments, rent a house every month, income than I tried to earn more, I a house, a monthly five-digit mortgage, this is not a class gap?

A: This is the accumulation of gaps between urban and rural areas and regions in history. People are local people, and the same accumulation reflects a different value. The same house, worth 10 million yuan in Guangzhou, rent 10, 000 yuan; 500, 000 yuan in the county, rent 1200; in the county countryside is the construction cost price, can not be rented.

CNMOULDING discusses this question, which is from his own yesterday. Despite our hard work, we have been running a company for over 20 years. But as a professional manufacturer of injection molding molds, I would say that we are not able to buy a good house in the inner ring of Shanghai. I am a relative, do an ordinary job, because I dare to buy a house, but live in a bigger house than I do.

Real estate has widened the gap between the rich and the poor in China.

2021年5月19日星期三

3d printing is cheaper alternatives for injection molding?

What is a cheaper way than 3D printing for injection molding

Look At It From the ABS Plastic Products

Why would you consider no 3D printing and injection molding

Tips of your choose

2021年5月11日星期二

What is the shot size in injection molding?

Basic parameters of injection molding machine

The basic parameters of the injection molding machine can better reflect the size of the injection molding products, the work capacity of the injection molding machine, and the evaluation of the type, grade range, and product quality of the processed materials. The basis for the selection and use of injection molding machines.

1. The injection quantity —— the maximum injection quantity that the injection system can achieve when the injection screw or plunger makes a maximum injection stroke under the condition of air injection.

To a certain extent, this parameter reflects the processing capacity of the injection molding machine, marks the maximum quality of the plastic products that can be formed by the injection molding machine, and is an important parameter of the injection molding machine. The PS standard (density ρ=1.05 g/cm3) is expressed by the mass (g) of the injected melt and the volume (cm3) of the injected melt

According to the definition, the theoretical value of the maximum injection capacity of the injection screw at one time is the product of the maximum projection area of the screw head in its vertical and axis direction and the stroke of the injection screw. QL =π/4 D2 S

The injection molding machine can not reach the theoretical value in the working process, because the density of plastic changes with the change of temperature and pressure, therefore, the injection capacity needs to be corrected properly. The modified injection capacity is Q=αQL =π/4 D2 Sα,α—— ejection coefficient, which is generally 0.7∽0.9,

The processing of plastic products on injection molding machines

the quality of generic products and the total amount of materials used in the gating system shall not exceed 25%∽70% of the injection molding quantity of the injection molding machine,

2. Injection pressure —— the force acting on the unit area of the melt by the end face of the screw or plunger. The size of the injection pressure is related to the injection molding machine structure, flow resistance, product shape, plastic properties, plasticizing mode, plasticizing temperature, requirements.

A 、 material fluidity is good, product shape is simple, arm thickness is big, the general injection pressure is less than 340∽540 Kgf/cm2. Applicable to the processing of LDPE, PA, and other materials.

The B、 material melt viscosity is low, the product precision is general, the injection pressure is 680∽980 Kgf/cm2. Applicable to the processing of PS, HDPE, and other materials.

The melt viscosity of C 、 material is medium or high, the precision of product is required, the shape is complex, the injection pressure is 980∽1370 Kgf/cm2., and the injection pressure is Applicable to the processing of PP, PC, and other materials.

D、 material has high melt viscosity, thin wall, long process, high precision, complex shape, the injection pressure of 1370∽1670 Kgf/cm2. Suitable for reinforced nylon, polysulfone, polyphenylene ether, and other materials processing.

E 、 processing high-quality precision micro-products, injection pressure can reach 2260∽2450 Kgf/cm2.

In order to meet the processing requirements of injection molding precision products or products with complex shapes of molding structure and engineering structural parts, the processing adaptability of the injection molding machine is enhanced, the molding period is shortened, and the product quality is improved. The injection pressure has a trend of increasing.

3. injection time (injection speed,)—— the melt began to cool after passing through the nozzle. In order to inject the melt into the mold cavity in time and obtain a dense, uniform, and high precision products, the melt must be filled with the mold cavity in a short time. In addition to sufficient injection pressure, there must be a certain flow rate.

4. plasticizing ability —— the amount of material that can be plasticized in unit time, and the plasticizing ability of general screw is related to screw speed, driving power, screw structure, material performance, and so on. The plasticizing device of the injection molding machine should be able to provide a sufficient amount of plasticized and uniform melt within the specified time, and the plasticizing ability should be coordinated with the whole molding cycle of the injection molding machine. The theoretical plasticizing ability of a general injection molding machine is more than 20% of the actual requirement.

2021年4月26日星期一

Career crisis at 35

CNMOULDING talk about China's 35-year-old workplace crisis

First,35-year-old employees are expensive, no cost-effective, no young people a high degree of cooperation.

I do business, not charity. Said to listen to the point called the staff, said that the bad point is the commodity, did not see me to use the price ratio? 70% new goods are more expensive than 90% new ones.

High EQ: It's our company's salary doesn't suit you

Second,35-year-old employees are not good "hoodwink ", more opinions

I want obedient college students like sheep, not you who know how to paddle and fish but also dare to talk back to the leaders because of overtime.

Hi EQ: It's our corporate culture that does n' t suit you

Third,35-year-old employees do not work hard, but also busy with housework.

You are all busy with your family. Who will work overtime for the company? You do not work overtime, my child's milk powder money how to come, my Mercedes who refueling me?

High EQ: our team atmosphere is not suitable for you.

The result of homogeneous competition is that the competitive cost of all participants is high, but the marginal income decreases or even returns to zero

There is a famous theater effect in economics like you're watching a show at the moment. If everyone is sitting and watching it is easy and clear, but if someone chooses to stand up, he will get a better view. The price is tiredness.

But the next problem is that other people's experiences get worse, and you have to stand up to deal with it. The final result was that everyone stood and watched the show. Very tired not to say vision is not necessarily better than sitting.

The same is true in the workplace, when all companies scramble to force employees to work overtime, the final result is that employees are tired, but the company may not be able to make better profitability. The eight-hour work system is how many years of labor groups strive for rights, this balance is not easy.

But many vested interests, like Ma Yun, hold this attitude of "overtime struggle is a blessing ". As people with more resources, they always threaten others to accept his rules. This is why we want to build a society ruled by law, even if sometimes under the choice of the rule of law, we do not seem so" progressive ".

But there is still a lot of struggles 13 is willing to do, the boss can be justified to say 996 you do not want some people willing.

Why the dinner roll?

Some people like to burn themselves, by the way, to ignite everyone

And finally, we're gonna hand in hand

Illuminate the capitalists.

But CNMOULDING is not such an enterprise, we pay more attention to the family sense and group nature of the enterprise. Our entire mold production team has been working together for more than 20 years, with rich working experience and team spirit is what we need for such an excellent plastic injection molding company. This is why we have been leading other companies.

2021年3月16日星期二

What is the real income of Shanghai,China?

Shanghai has become an international city. Consumption is also becoming more and more expensive. We must be very interested, Shanghai works in various industries, how much do they earn?

Cnmoulding as a production injection molding company. There are 40 employees, basically, each engineer's income is 15000 yuan.(2500usd/month)

|

Let's look at other companies.

The following are several 18,19,20 years of graduates, majoring in computer, automation, communications, electronics. The following are all school pay, before tax.

-----------------------------

Let's start with computers:

Inner ring a state-owned enterprise, computer doctor, about 400000.

Meituan, computer doctor, about 40-500,000.

Master of computer, generally more than 300000.

A university in Shanghai, computer doctor, lecturer, more than 10,000 a month, annual salary estimated 180000.

Another suburban university, computer doctor, lecturer,180000.

--------------------------------------

Other professions:

Shunfeng, UAV Research, Master,300000.

Zhang Jiang small-scale science and technology private enterprises, doctor,300000.

Pudong Automobile Foreign Enterprise, autopilot, Master, an individual can reach 300000.

Pudong automation industry famous foreign enterprises, doctor,250000.

Jiading a medical technology company, master less than 200000, doctor about 250000.

Pudong a patriotic factory, master unified cabbage price of 250000, the doctor seems to be 350000.

Minhang a research institute, doctor, a monthly salary of 17000, an annual salary of about 300000.

A famous automotive electronics company, master 200000, doctor 250000.

Southwest suburb of an automobile private enterprise research institute, doctor about 230000.

A famous video security company, the master, seems to be 200000.

Minhang many aerospace research institutes, doctor 18-27 million, master less than 180000.

Pudong heavy industry manufacturing enterprise, the doctor estimated 180000, master's monthly salary of 10,000.

Shanghai near Kunshan a heavy industry manufacturing industry, doctor,180000.

Caohejing Internet enterprises, master, the monthly salary of 17000, the annual salary of about 200000.

Pudong an aircraft industry, the doctor seems to be less than 200000,(heard that a master of machinery to 6000 a month).

Shanghai auto industry leader, master unified 170000(heard that the impact of the epidemic wages fell 40%).

Xu Huimou Institute, Ph. D., the monthly salary of 10,000, the estimated annual salary is not more than 160000.

North of an aircraft factory, master, monthly salary less than 10,000.

A ship research institute, Bo Hou, heard that the monthly salary of 8,000.

----------------------------

Supplementary note:

The same number, different enterprises will give differently.

Most of them refer to pre-tax wages, but some companies like to promote corporate costs.

Some state-owned enterprises have dormitories, canteens, supplementary provident fund and other benefits, the hands may be more.

Some private companies may not pay five risks and one gold in full.

Some places may go into lower wages, others increase wages every year.

Some are general packages, and some hide benefits that are not publicly available.

Some companies 996, some companies 955.