2021年5月19日星期三

3d printing is cheaper alternatives for injection molding?

2021年5月16日星期日

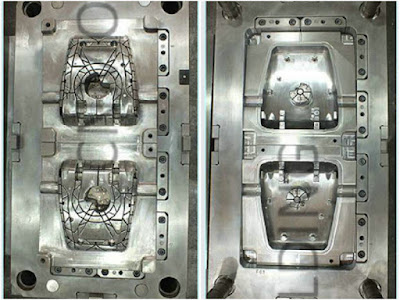

What is the standardization of an injection mold design?

Tips for Standardization of Injection Mold Design

The detailed design standard of the molding structure is determined according to the molding classification, central system, cold and hot system, injection system, inclined cover mechanism, and sliding mechanism.

General standardized dimensions of the instrument.

According to the standard size type and product size of each die board, you can consult the mold company's standardized form.

auxiliary structures constructed to inform, such as points, lines, planes, and surfaces, must be closed and opened from the specified plane, and the name of the plane must be consistent.

Configure synchronous design rules so that many engineers clearly define activities and do not interfere with each other when creating the same toolkit.

1) shall establish a unified mold design framework according to the actual needs of the company, and the position of the mold parts in the framework should be standardized.

2) standardized general mold sizes. According to the standard size model and product size of each mold plate, refer to the standard of company mold.

3) has formulated detailed design standards for mold structures according to the classification of molding components, gating systems, hot and cold systems, injection systems, inclined roof mechanisms, and slider mechanisms.

4) mold parts preferred standard parts, standard parts can be processed by the company's own standard parts, or for professional standard mold parts companies (such as HASCO、DME、MISUMI、 ZhengGang, etc). Standard components for production.

5) for highly structured products, build a special injection mold library according to the size of the product to shorten the design time. For example, according to the number of electric vehicles, a mold library should be established corresponding to the electric vehicle cover and bottom casing.

6) established rules for synchronous design, enabling many engineers to identify tasks when designing the same set of modules without interfering with each other.

The auxiliary design in mold design, such as point, line, plane, and surface, shall be closed according to the specified layer, and the layer name is uniform.

2021年5月13日星期四

What are the five types of polymer additives

About additive

an additive developed by polymers to improve the processing properties of polymers. Applications include film, blow molding, extrusion, monofilament, fiber, pipe, wood plastic, sheet and wire, and cable. It has the following effects :1, Like the usual melt rupture, Improve the brightness and smoothness of the product surface. Make the color more uniform, Shinier. Reduce the wear and tear of the mold during processing, Eliminate the phenomenon of die accumulation. Reduce the gel produced during extrusion. Reduce processing temperature and extend continuous processing time. 6. Improving the molding rate and dimensional stability of the product, Reduce waste rate. Applicable material (M) LLDPE, LDPE, HDPE, PE-RT, PVC, PA, PS, ABS, PP, BOPP, CPP and other materials working principle when the addition of polymer processing aids in the extrusion process, Under the influence of potential difference, The tendency of fluorinated polymers to move to the outer layer of the melt and attach to the metal surface, Form a lubricating layer between the metal wall and the polymer melt (which takes 1-3 hours to form, depending on the machine size). During continuous extrusion, This coating is in dynamic equilibrium, When the dynamic equilibrium is stable, the Extrusion process and product quality will be stable. The typical addition range PPA addition amount is PPM,300-1200 The influence of other additives and processing technology in basic resin should be considered.

Plastic and Polymer Additives

Plastic has the advantages of a lightweight, corrosion resistance, high strength, excellent electrical properties, and easy processing. All kinds of beautiful and colorful products made from it have become an essential material for people to dress, eat, live and walk. However, plastics are not perfect, such as some plastics are too brittle, some flammable, some easy to start static electricity and so on, so a variety of additives (also known as auxiliaries) must be added to improve the properties of plastics.

With the rise of the plastic industry, as an indispensable additive for plastic processing, it must develop synchronously, and has become a fine chemical industry with a wide variety and considerable scale. Now the annual consumption of plastic additives is about 11% of the consumption of plastic. There are many varieties of plastic additives, and several of the main types are described below.

The antioxidant is a chemical additive that can inhibit or delay the automatic oxidation reaction. Plastic in the process of processing, storage, and use, under the action of light, heat, and oxygen, will fade (yellowish), weight loss, become opaque, powder and surface cracking, this phenomenon is called aging phenomenon. With the aging of plastics, products will lose their use-value.

80% of the total amount of antioxidants is used in three kinds of polymers: polypropylene, polyethylene and polystyrene.

The plasticizer is a kind of material added to material (plastic, resin) to improve its processability, softness, stretchability.

Polyvinyl chloride (PVC) was developed into a widely used synthetic resin after the plasticizing process was solved.

The amount of plasticizer used in PVC accounts for 80% of the total plasticizer consumption. Stabilizer light stabilizer is a compound that can inhibit the degradation reaction caused by light induction. Usually refers to organic or organometallic compounds that only slightly fade or not fade plastic. Almost 75% of the light stabilizers are used in polyolefin resins, in which the light stable dose for polypropylene is equal to the sum of the light stable doses of all kinds of polyethylene resins. Visible, light stable

The agent is of special significance to polypropylene.

Metal activator is a kind of compound that can form inactive or almost inactive with metal with catalytic activity. The chelating agent can form a metal complex with high thermal stability. Metal activators are mainly used in communication wires with polyolefin as insulating material.

Lubricant

Lubricant is a compound that can reduce the friction resistance between the surfaces of product parts at service temperature. This additive is especially important for polyethylene film.

The anti-flushing modifier is a kind of polymer material to improve the toughness of plastics. Generally, a polymer anti-flushing modifier is added to improve the impact resistance of thermoplastic plastics. At present, in the world plastic additive market, about 15% of the anti-flushing modifiers,90% of which are used in rigid PVC products.

PVC anti-scour modifiers include chlorinated polyethylene, ABS、MBS( methyl methacrylate / butadiene / styrene terpolymer), polypropylene impact modifier has ethylene propylene rubber.

Packing and reinforcing materials

A filler is a solid additive that is different in composition and structure from that of a plastic matrix by adding a polymer

In order to increase volume, improve its properties, reduce costs, usually inorganic; reinforced fillers are materials used to improve some mechanical and physical properties of polymers, such as improving the tensile strength of materials. Fillers and reinforcement materials are carbonates, glass fiber, aluminum hydroxide, and so on.

Colorants

A colorant is, as the name implies, a dye or pigment that gives color to a plastic. Pigments are more important to the plastics industry

Large, not only general pigments but also fluorescent, pearlescent and other decorative pigments. In the plastic industry, pigments are often pre-added to another resin (color carrier) that has good compatibility with the processed plastics to make "concentrated color" or "color masterbatch ". It can achieve uniform color and firm effect instead of pigment, and no dust pollution during operation.

Flame retardant

Flame retardant is a compound that can prevent combustion, reduce combustion speed or increase ignition point. Because plastic is rich

Organic materials containing carbon and hydrogen are flammable and must be flame retardant in use to meet the requirements of flame retardancy.

Antistatic agents

An antistatic agent is a compound that reduces the chargeability of polymers. Since plastics are insulating materials, they are

When the material is in contact, the charge transfer will produce static electricity, so the plastic product is easy to adsorb dust, so an antistatic agent must be added to the processing.

Foaming agent

The foaming agent is a combination that can release gas by chemical reaction and make polymer body produce foam structure

Things. Foam is plastic produced with a foaming agent.

To correctly grasp the characteristics of various plastic additives, the scope of use and the amount of added can produce beautiful and durable plastic products.

2021年5月11日星期二

What is the shot size in injection molding?

Basic parameters of injection molding machine

The basic parameters of the injection molding machine can better reflect the size of the injection molding products, the work capacity of the injection molding machine, and the evaluation of the type, grade range, and product quality of the processed materials. The basis for the selection and use of injection molding machines.

1. The injection quantity —— the maximum injection quantity that the injection system can achieve when the injection screw or plunger makes a maximum injection stroke under the condition of air injection.

To a certain extent, this parameter reflects the processing capacity of the injection molding machine, marks the maximum quality of the plastic products that can be formed by the injection molding machine, and is an important parameter of the injection molding machine. The PS standard (density ρ=1.05 g/cm3) is expressed by the mass (g) of the injected melt and the volume (cm3) of the injected melt

According to the definition, the theoretical value of the maximum injection capacity of the injection screw at one time is the product of the maximum projection area of the screw head in its vertical and axis direction and the stroke of the injection screw. QL =π/4 D2 S

The injection molding machine can not reach the theoretical value in the working process, because the density of plastic changes with the change of temperature and pressure, therefore, the injection capacity needs to be corrected properly. The modified injection capacity is Q=αQL =π/4 D2 Sα,α—— ejection coefficient, which is generally 0.7∽0.9,

The processing of plastic products on injection molding machines

the quality of generic products and the total amount of materials used in the gating system shall not exceed 25%∽70% of the injection molding quantity of the injection molding machine,

2. Injection pressure —— the force acting on the unit area of the melt by the end face of the screw or plunger. The size of the injection pressure is related to the injection molding machine structure, flow resistance, product shape, plastic properties, plasticizing mode, plasticizing temperature, requirements.

A 、 material fluidity is good, product shape is simple, arm thickness is big, the general injection pressure is less than 340∽540 Kgf/cm2. Applicable to the processing of LDPE, PA, and other materials.

The B、 material melt viscosity is low, the product precision is general, the injection pressure is 680∽980 Kgf/cm2. Applicable to the processing of PS, HDPE, and other materials.

The melt viscosity of C 、 material is medium or high, the precision of product is required, the shape is complex, the injection pressure is 980∽1370 Kgf/cm2., and the injection pressure is Applicable to the processing of PP, PC, and other materials.

D、 material has high melt viscosity, thin wall, long process, high precision, complex shape, the injection pressure of 1370∽1670 Kgf/cm2. Suitable for reinforced nylon, polysulfone, polyphenylene ether, and other materials processing.

E 、 processing high-quality precision micro-products, injection pressure can reach 2260∽2450 Kgf/cm2.

In order to meet the processing requirements of injection molding precision products or products with complex shapes of molding structure and engineering structural parts, the processing adaptability of the injection molding machine is enhanced, the molding period is shortened, and the product quality is improved. The injection pressure has a trend of increasing.

3. injection time (injection speed,)—— the melt began to cool after passing through the nozzle. In order to inject the melt into the mold cavity in time and obtain a dense, uniform, and high precision products, the melt must be filled with the mold cavity in a short time. In addition to sufficient injection pressure, there must be a certain flow rate.

4. plasticizing ability —— the amount of material that can be plasticized in unit time, and the plasticizing ability of general screw is related to screw speed, driving power, screw structure, material performance, and so on. The plasticizing device of the injection molding machine should be able to provide a sufficient amount of plasticized and uniform melt within the specified time, and the plasticizing ability should be coordinated with the whole molding cycle of the injection molding machine. The theoretical plasticizing ability of a general injection molding machine is more than 20% of the actual requirement.

2021年5月10日星期一

CNMOULDING succeed invest smart watch

Smartwatch is a watch with information processing ability and meets the basic technical requirements of the watch. Its functions are similar to that of a personal digital assistant. In addition to indicating time, it should also have one or more functions, such as a compass, pedometer, touch screen, global positioning system, and as a large storage device, which includes a pointer, number, image, and so on. World-famous technology companies such as Apple, Samsung, Sony and so on have been involved in the development and research of the product, representing the products of Apple iwatch、 Google watches, Sony SmartWatch、 Epson smartwatch PS-500 and so on.

Recently, CNMOULDING successfully developed a project for customers. By modifying the structure of the product, we reduced the whole development cost by 50% in injection mold development and 20-30% in plastic production.

The success of this smartwatch will be the best preparation for our later development of similar smart electronic wearable devices and reduce development costs.

More about WEARABLE DEVICE

A wearable device is a portable device that is directly worn on the body or integrated into the user’s clothes or accessories. Wearable devices are not only a kind of hardware devices. But also realize powerful functions through software support, data interaction, and cloud interaction. Wearable devices will bring great changes to our lives and perceptions.

Wearable devices mostly exist in the form of portable accessories that have some computing functions and can be connected to mobile phones and various terminals. The mainstream product forms include wrist-supported watches (including watches and wristbands), and feet-supported shoes (including shoes, socks, or other products worn on the legs in the future), glasses with head support (including glasses, helmets, headbands, etc.), and various non-mainstream non-mainstream such as smart clothing, school bags, crutches, and accessories Product form.

SMART BRACELET

The smart bracelet is a wearable smart device. Through this bracelet, users can record real-time data such as exercise, sleep, some food, etc. In daily life, and synchronize these data with mobile phones, tablets. And iPod touch, playing a role in guiding healthy life through data.

The main body of the smart bracelet is generally made of medical rubber, memory rubber, environmentally friendly plastic, natural and non-toxic. The appearance design is high-end and fashionable, generous. Not only has the function of sports health secretary but also has the function of fashion accessories. The appearance has streamlined wreaths and various colors. There are silver coated metal caps on both ends, which are very suitable for wearing. Which also makes it different from traditional bracelets with buckles or buttons. The smart bracelet has a built-in lithium battery with a battery life of up to 10 days, a vibration motor, and a motion-sensing accelerometer. The small silver cap at the end of the bracelet is a button for changing settings. And the other section is a 3.5 mm plug for connecting to a mobile phone.

The design style of a smart bracelet is quite tempting for users who are used to wearing jewelry. More importantly, the design style of the bracelet is versatile. Moreover, regardless of the size of the small bracelet, its function is quite powerful. For example, it can be said to be a high-end pedometer, with the general step counter of a normal pedometer, measuring distance, calories, fat, and other functions. It also has special functions such as sleep monitoring, high-end waterproof, Bluetooth 4.0 data transmission, and fatigue reminders.

APPLICATION FIELD

The advent of the era of wearable smart devices means the extension of human intelligence. Through these devices, people can better perceive external and own information. Can process information more efficiently with the assistance of computers, networks, and even other people, and can achieve more seamless communication. Application areas can be divided into two categories, namely self-quantification and in vitro evolution.

In the field of self-quantification, the two most common application segments are the field of sports and fitness outdoor. And the other is the field of medical care.

In the field of sports and fitness outdoor, the main participating manufacturers are professional sports outdoor manufacturers and some start-up companies. They use lightweight watches, bracelets, and accessories as the main form to achieve sports or outdoor data. Such as heart rate, cadence, air pressure, diving depth, Monitoring, analysis. And service of indicators such as altitude.

In the field of healthcare, the main participating manufacturers are medical portable device manufacturers. Which provides specialized solutions for the detection and treatment of blood pressure, heart rate. And other medical signs in various forms, including medical vests, belts, and implantable chips.

2021年5月7日星期五

Smart cars are growing so fast

CNMOULDING began to produce automotive injection molded parts for TESLA matching

Today I will share some of my views on Smart Cars

Later, whether Wei Lai, Xiaopeng, or Xiaomi are basically along these two roads.

A debate remains over whether smart driving and smart cockpit should merge as if horizon had organized a debate on both sides before the shanghai auto show.

Self-learning and evolutionary ability will become the core difference between the new generation of the intelligent cockpit and the traditional generation of the intelligent cockpit.

2021年4月26日星期一

Career crisis at 35

CNMOULDING talk about China's 35-year-old workplace crisis

First,35-year-old employees are expensive, no cost-effective, no young people a high degree of cooperation.

I do business, not charity. Said to listen to the point called the staff, said that the bad point is the commodity, did not see me to use the price ratio? 70% new goods are more expensive than 90% new ones.

High EQ: It's our company's salary doesn't suit you

Second,35-year-old employees are not good "hoodwink ", more opinions

I want obedient college students like sheep, not you who know how to paddle and fish but also dare to talk back to the leaders because of overtime.

Hi EQ: It's our corporate culture that does n' t suit you

Third,35-year-old employees do not work hard, but also busy with housework.

You are all busy with your family. Who will work overtime for the company? You do not work overtime, my child's milk powder money how to come, my Mercedes who refueling me?

High EQ: our team atmosphere is not suitable for you.

The result of homogeneous competition is that the competitive cost of all participants is high, but the marginal income decreases or even returns to zero

There is a famous theater effect in economics like you're watching a show at the moment. If everyone is sitting and watching it is easy and clear, but if someone chooses to stand up, he will get a better view. The price is tiredness.

But the next problem is that other people's experiences get worse, and you have to stand up to deal with it. The final result was that everyone stood and watched the show. Very tired not to say vision is not necessarily better than sitting.

The same is true in the workplace, when all companies scramble to force employees to work overtime, the final result is that employees are tired, but the company may not be able to make better profitability. The eight-hour work system is how many years of labor groups strive for rights, this balance is not easy.

But many vested interests, like Ma Yun, hold this attitude of "overtime struggle is a blessing ". As people with more resources, they always threaten others to accept his rules. This is why we want to build a society ruled by law, even if sometimes under the choice of the rule of law, we do not seem so" progressive ".

But there is still a lot of struggles 13 is willing to do, the boss can be justified to say 996 you do not want some people willing.

Why the dinner roll?

Some people like to burn themselves, by the way, to ignite everyone

And finally, we're gonna hand in hand

Illuminate the capitalists.

But CNMOULDING is not such an enterprise, we pay more attention to the family sense and group nature of the enterprise. Our entire mold production team has been working together for more than 20 years, with rich working experience and team spirit is what we need for such an excellent plastic injection molding company. This is why we have been leading other companies.