What is a cheaper way than 3D printing for injection molding

Compared with 3D printing, there is no other process with speed perfect, injection molding offered in plastic.

Look At It From the ABS Plastic Products

One thing you need to consider is being hard to use ABS, if you do some handmade

Because it is non - definite plastic, it means that workers must judge whether the plastic is liquid or still semi - isolated. This may mean some skilled labor, which will make it expensive.

Hand heat pour plastic in the mold, then vibrates until it bubbles out, and then more plastic is added and again the vibration should work in theory. The challenges you may face include safety, from hydrothermal ABS (nearly 120 °C), preventing liquids from splashing around, and finding the appropriate vibration mechanism to eliminate bubbles.

One problem with injection molding is air. The air in a set of ABS molds weakens your structure and sometimes significantly. Therefore, manually placing the liquid ABS in the mold will give you a challenge of structural strength that can be easily be vibrated or overcome in vacuum.

Why would you consider no 3D printing and injection molding

You don t want to use 3d printing - probably due to higher initial costs and poor physical properties.

You don't want to use injection molding - maybe you don't need the amount, the initial mold production investment is high because you don't know-how

You can choose alternative processes such as vacuum molding, sheet molding, hand laying, spray spraying, etc. You can also choose from a prototype molding (aluminum) or resin molding.

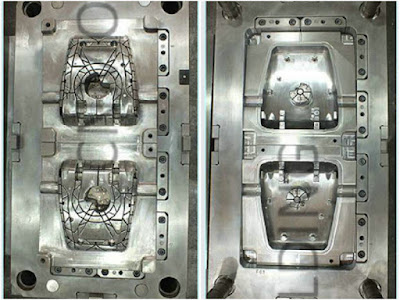

The most common one is the aluminum mold, initial cost, availability and size; performance accuracy.

But I need to tell you that it is very stupid to do.

Tips of your choose

3D printing is not designed for high-volume injection molds but can be used for low-volume operation. Mass product production, first you need to produce high-quality simple or complex molds. The choice of steel material molds instead of solid 3D long fibers can form stronger shells that inject pressurized liquid plastic into it. Aluminum mold is not recommended, inconvenient for modification, and also

The product appearance quality is not as good as the steel mold.

没有评论:

发表评论