**Injection Molding of Glass Fiber Reinforced Nylon: A Comprehensive Solution for Combustion Applications**

Injection molding has long been a cornerstone of modern manufacturing, offering unparalleled precision, scalability, and efficiency. When combined with advanced materials like glass fiber reinforced nylon, this technique opens doors to innovative solutions for demanding applications, particularly in combustion systems. In this blog post, we’ll explore how this composite material is revolutionizing the field of injection molding and why it is an ideal choice for combustion-related components.

### Understanding Glass Fiber Reinforced Nylon

Glass fiber reinforced nylon is a composite material consisting of nylon resin embedded with finely chopped glass fibers. Nylon, a synthetic polymer, is already well-regarded for its durability, flexibility, and chemical resistance. The addition of glass fibers enhances its mechanical properties, including tensile strength, stiffness, and thermal stability. This makes it particularly suited for applications where materials must endure high temperatures, mechanical stress, and aggressive chemical environments.

### Why Glass Fiber Reinforced Nylon for Combustion Applications?

Combustion systems—whether in engines, industrial burners, or heating systems—operate under extreme conditions. Components in these systems must withstand elevated temperatures, pressure fluctuations, and exposure to corrosive gases. Glass fiber reinforced nylon addresses these challenges through its unique combination of properties:

1. **High Heat Resistance**: The material maintains structural integrity at temperatures exceeding those tolerated by standard plastics. This makes it ideal for components like intake manifolds and exhaust system parts.

2. **Mechanical Strength**: The reinforced fibers provide enhanced rigidity and durability, allowing parts to resist deformation under mechanical loads.

3. **Chemical Resistance**: Nylon naturally resists degradation from oils, fuels, and other chemicals commonly found in combustion environments.

4. **Lightweight Design**: Compared to metals traditionally used in combustion systems, glass fiber reinforced nylon offers a lighter alternative without sacrificing performance. This contributes to improved fuel efficiency in automotive applications.

5. **Cost Efficiency**: Injection molding with this composite material is highly cost-effective for producing complex geometries at scale.

### The Injection Molding Process

The injection molding process for glass fiber reinforced nylon follows similar steps to traditional injection molding but requires specialized considerations due to the material’s unique properties:

1. **Material Preparation**: The nylon resin and glass fibers are blended to ensure a uniform distribution of reinforcement throughout the polymer matrix.

2. **Melt Processing**: The blend is melted at high temperatures within the injection molding machine. Precise temperature control is critical to prevent degradation of the polymer or fibers.

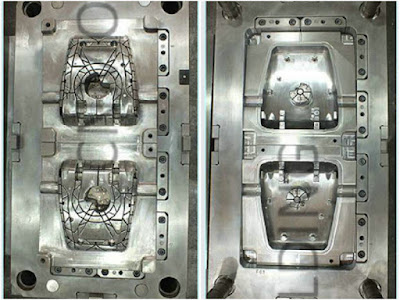

3. **Mold Design**: Molds must be engineered to accommodate the flow characteristics of glass fiber reinforced nylon, ensuring even distribution and minimizing fiber breakage during injection.

4. **Cooling and Solidification**: Once injected into the mold cavity, the material cools and solidifies into the desired shape. Cooling rates must be carefully managed to avoid warping or internal stresses.

5. **Post-Processing**: Finished parts may undergo additional treatments such as trimming, surface finishing, or annealing to enhance their performance characteristics.

### Applications in Combustion Systems

Glass fiber reinforced nylon has proven its value across a wide range of combustion-related applications. Common examples include:

- **Automotive Components**: From air intake manifolds to engine covers, this material delivers lightweight strength and heat resistance critical for modern vehicles.

- **Industrial Burners**: Structural components in burners benefit from the material’s ability to withstand prolonged exposure to high temperatures.

- **Heating Systems**: Parts like flue gas ducts and blower housings leverage the material’s chemical resistance and durability.

### Challenges and Considerations

Despite its advantages, working with glass fiber reinforced nylon does present some challenges. For example, its abrasive nature can cause wear on injection molding equipment over time. Additionally, achieving consistent fiber orientation during molding requires meticulous design and process control. Manufacturers must also account for potential shrinkage or warping during cooling.

### Conclusion

Glass fiber reinforced nylon is a game-changer for injection molding applications in combustion systems. Its unique combination of heat resistance, mechanical strength, chemical durability, and lightweight properties make it an ideal choice for demanding environments. By leveraging advanced injection molding techniques and addressing material-specific challenges, manufacturers can unlock new possibilities for innovation in combustion technology.

As industries continue to push the boundaries of performance and efficiency, materials like glass fiber reinforced nylon will undoubtedly play a pivotal role in shaping the future of manufacturing.